By now, transparency in building material ingredients has shifted from a buzzword to a bona fide movement. With the uptake of Health Product Declarations (HPDs) in LEEDv4, awareness of the content of our built environment and the corresponding health and environmental impacts is on the rise. Transparency of material ingredients in the building products industry is mirroring a broader trend for the demand for transparency of all types: consumer products, business practices, even politics (tax returns, anyone?). In a 2012 blog post by Interface, it was noted that “in a few years’ time” full product transparency would be as typical as corporate sustainability reporting and nutrition labeling. While that has not quite come to fruition, more recently a food industry study identified “full product transparency” as a priority that brands can utilize to acquire and maintain customers, especially as brand loyalty diminishes. Indeed, the global consumer cleaning product company SC Johnson facilitated an industry discussion on the “opportunities and challenges for transparency and how it affects consumer trust” at a conference earlier this year. This follows the 2009 launch of their transparency website, WhatsInsideSCJohnson, which lists information on their product ingredients.

The call has been building for a decade or more now, perhaps not surprisingly coinciding with the rise of the millennial generation—a group well known for their civic-mindedness [1], sense of social justice, as well as a sense of entitlement. [2] Between the internet (free and open access, hence our “right” to this information) and Big Data, well, if the information exists we should be able to see it and make our own decisions about it.

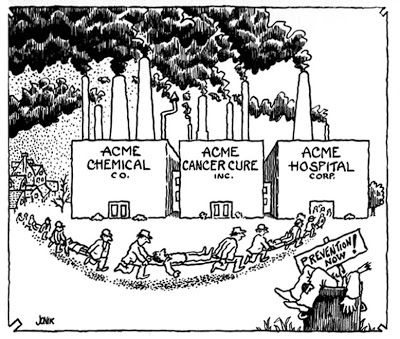

As it turns out, we need to start making better decisions when it comes to chemicals used to make the places we work, sleep, worship, play, heal, and learn in (in other words, the built environment). Chemical regulations are built around the idea of “safe until proven harmful” – with the burden of proving harm falling to the EPA, which is widely acknowledged to be understaffed and underfunded for this effort. While science chips away at the lack of data with piecemeal health and hazard studies, synthetic chemicals are cropping up in places they were never intended to be: inside the bodies of polar bears, in crustaceans at the bottom of the ocean, in air and water currents, soil, and perhaps most disturbingly, in the blood of our babies. The body burden of the chemicals we are all now subject to arises from a multitude of sources, including:

- Every airplane, car, or train ride exposes us to higher levels of flame retardants;

- Every squirt of perfume, hair gel, shaving cream, or body lotion rubs phthalates and parabens into our skin;

- Every bite of food held in BPA-lined cans, delivered to our door in PFC-coated plastic cardboard, or treated with pesticides enables more of these toxic molecules to find their way into our bodies.

Without our knowledge, without our consent. Millennials aren’t the only ones who think this is just plain wrong.

But how does just knowing something, like the ingredients in a product, change anything? It’s the decisions we make based on that knowledge that fosters change. In the same way that being able to compare food nutrition labels at the grocery allows us to make healthier food choices, the availability of hazard data (toxic ingredients) allows us to make healthier product choices. Healthier for our clients, and healthier for the planet: with global supply chains, our choices have deeper and broader implications than ever.

Especially, synthetic chemicals have become more and more pervasive in building construction – as exterior finishes as well as inside. In particular, chemicals based on oil can be found in everything from adhesives and high performance coatings to carpet and wall coverings. It needs to be understood that what begins as waste product from the gas and oil-refining industry (6.8 gallons of a 55-gallon barrel) is now the backbone of the design and construction industry. The ultimate flaw with this chemistry is that to be used for such a wide range of products, many more chemicals must be added, simply compounding the potential health and environmental impacts. [3]

Let’s look back just ten years ago: there were no “red lists” for a designer to use to screen out problematic substances from a project. In fact, the only guidance around “green” or healthy building materials focused on indoor air quality, such as emissions from formaldehyde or VOC limits on wet-applied adhesives and paints. There was, however, one design studio interested in reducing all problematic substances on their projects: Guenther 5 Architects. In the mid-90’s, Robin Guenther began researching and speaking about potential health issues associated with common building products. As a healthcare architect, she had learned how chemicals associated with everyday materials can impact vulnerable populations. “We had two projects in the office: a bone marrow transplant unit and an apartment renovation for a person with Multiple Chemical Sensitivity (MCS). We learned about the connection between the spaces we live in and human health,” she recalls. It was around the same time the healthcare industry also got a wake-up call. “In 1996, the US EPA published a finding that medical waste incineration of PVC plastics was the second largest source of dioxin [a known carcinogen] emissions in the US. For me, it was ironic that the industry pledged to health would be an industrial scale polluter. That was another indicator that the materials we surround ourselves with could damage our collective health. It underscored the need to understand the chemical make-up of the building products we were specifying – and it was something almost no one else seemed to be doing.”

By 2006, she and her team were working on the “practice gap” – the gap between knowing health hazards lurked in products and actively searching out alternatives. Her partner Peter Syrett, alongside interior designer Chris Youssef, led the charge to “clean out the library,” culling the worst-in-class products. They established criteria used for vetting products in the sample library, and developed a “red list.” By 2008 (after Guenther 5 Architects was acquired by Perkins+Will), this initial spreadsheet effort had coalesced into the Perkins+Will Precautionary List.

While the Precautionary List provides a framework to bridge over the practice gap, the work is far from complete. Now that we know what chemicals to look for, getting the actual ingredient data for products is still a challenge. Manufacturers were (and still are) concerned about giving away their proprietary information. Architects and designers were (and still are) concerned about liability and scope creep. And seemingly only a handful of design professionals were (and still are) talking about transparency—conventional wisdom told us this concern was not even on the radar for clients. If it was true then, it definitely is not true now: according to a Dodge Data and Analytics report published last year, 30 percent of project owners are interested in product transparency information, yet only 10 percent of architects and interior designers (and 15 percent of contractors) believe the owners are interested. As time goes on, the number of interested owners is sure to rise. When your client (project owner) is one of the users of SC Johnson’s transparency site or other consumer goods toxic ingredient guides because they have noticed the chemicals in their personal lives, it’s a natural pivot for them to then ask “what’s in it?” of their project work.

Besides acquiring the information, another challenge lay in the data itself: as we learn what is in the building products being considered for a project, what do we do with it? What does it mean? Just because a hazard exists, does it mean there is an actual risk? And risk to whom—the installer? The end user? The factory worker? Can data coming directly from the manufacturer be trusted? Is it complete? What does “complete” mean, when a product may be made of component parts, some of which may be supplied by a vendor with non-disclosure agreements in place? These questions are being worked through, mostly by trial and error, as more and more project teams are tackling the issue. One big breakthrough on the data side has been the development of the Health Product Declaration (HPD). This document allows manufacturers to provide their data in a standardized format, so designers can compare apples to apples. In addition, the hazards are listed even if the chemical names are not (allowing proprietary information to remain hidden) so health effects can still be taken into consideration.

Lucile Packard Children’s Hospital, Stanford, a large facility located in the heart of California’s Silicon Valley, began design about ten years ago. From day one, this privately funded institution focused on providing the most resource-conserving facility possible, while holding the patient experience in highest priority: daylight, artwork, and local materials dominate the project, which is opening in December 2017. “Healthy materials” was also a specific project goal, and the project team steered product choices toward lower-toxicity options.

Ten years later, there is no vinyl flooring to be found in the facility, thanks to the forward-thinking design team. Looking at finishes through the lens of health and patient experience, durability and ease of maintenance became drivers over first cost (for example, back-painted glass in lieu of plastic wall protection in patient areas). Because of the strong color story, closely related to the graphics throughout which identify each floor according to a local ecosystem of flora and fauna, each product became part of the “ecosystem” of patient experience—their value together greater than any single line item cost.

Based on these experiences, and others, our approach to design is shifting: consider materials from structure and enclosure to flooring and walls at the outset: these (often default) selections become embedded into the project as budgets and schedules develop around them, making it difficult to change even at the design development stage. A strong design concept in which color and texture are important components also builds a case for products as specified (minimizing last minute changes and “value engineering” of finishes). Identify a team-wide reference (like the Precautionary List or other defined strategy) for product vetting, and have the health champions from each stakeholder (and there should be a champion with every consultant, including the owner’s and contractor’s teams) on board with protocols for substitutions and alternates.

Consumer awareness continues to drive transparency, at multiple levels. As millennials take over more and more companies, with their values-based drives, more businesses will make transparency the status quo. The trickle-down effect of transparency at the brand level is that eventually the supply chain must also step up. Many will do so willingly; the force of economics will drag others along. Either way, everyone wins: manufacturing processes that rely less on hazardous chemicals results in the production of fewer hazardous chemicals, resulting in fewer communities near factories taking the brunt of direct environmental pollution on our behalf, and ultimately fewer hazardous chemicals streaming through all our bodies.

The power of transparency will transform the world, starting by changing the manufacturing processes (and mindset) that treat the planet as a chemical sink. As consumer awareness has created new market niches, influenced some brands to clean up their formulas, and given some businesses a marketing advantage, maybe transparency will even transform politics as we know it. Nah, probably not.

[1] Strauss, William; Howe, Neil (2000). Millennials Rising: The Next Great Generation. Cartoons by R.J. Matson. New York, NY: Vintage Original. p. 370. ISBN 0-375-70719-0. [2] Twenge, Ph.D., Jean (2006). Generation Me. New York, NY: Free Press (Simon & Schuster). ISBN 978-0-7432-7697-9. [3] Robin Guenther. Keynote. Living Product Expo, International Living Future Institute, September 2016, Pittsburgh, Pennsylvania.

I had no idea that synthetic materials have become more pervasive in building construction. I wouldn’t want harmful chemicals to be in my materials. I’ll make sure they are all clean of those things before building anything.